Warehouse automation: Innovation and efficiency, working together with people for guaranteed success

In the last few years, we have seen an acceleration in the transition to automation, with the role of technology and automation taking centre stage.

The MHI and Deloitte Global Industry Annual Reports for 2022 and 2023 provide valuable insights into how the intralogistics industry is responding to the challenges and opportunities presented by the evolution of technology and the implementation of automation and robotics. Amidst all the progress, it is essential to highlight one important point: even as automation develops, the need for human labour will remain indispensable.

Automation evolution 2022-2023

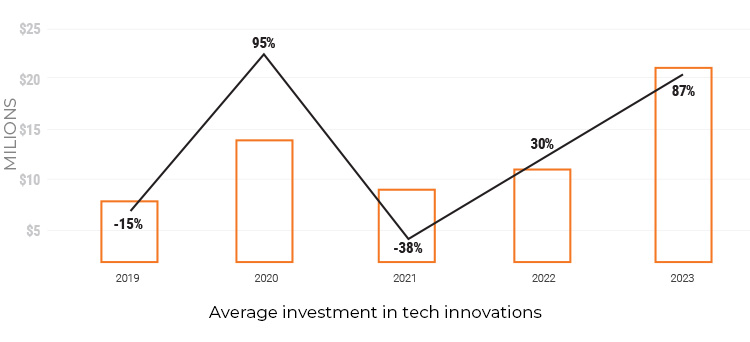

According to last year’s report, companies have recovered from the COVID-19 pandemic and increased their spending on supply chain innovations, with a focus on technologies such as robotics and automation. This trend continues to grow in 2023: more and more companies are planning major investments, with 90% planning to invest more than $1 million in automation, up 24% from last year.

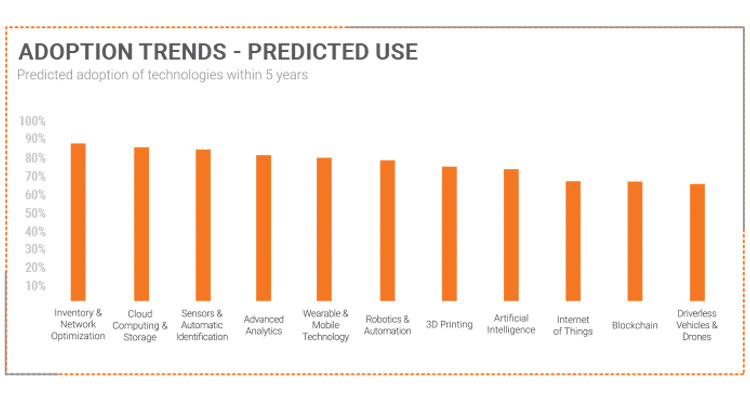

As early as 2022, robotics and automation were considered the top innovations in the industry, with other technologies with significant potential including automated sensing and identification, autonomous vehicles and artificial intelligence technology. Although artificial intelligence gained prominence in 2023, robotics and automation continue to top the list of innovations, showing the potential to make real and transformative differences in the industry. Furthermore, this year’s report states that all of these technologies are expected to reach an adoption rate of over 66% in the next 5 years.

“Investments in automation and other digital solutions like IoT, advanced analytics and AI arm your operations with speed, accuracy and improved visibility. These solutions enable the real-time decision making and transparency necessary for reporting and improving performance up and down the responsible supply chain.”

John Paxton, Director general MHI

The human value in automation

While technology is a powerful aid in any industry, it is not a stand-alone solution. So successful digital transformation involves adopting the right work culture and bringing the right people together. The synergy between technology and people is key to exceeding customer expectations. With automation at its core, human expertise and adaptability are at the forefront of technology implementation.

In both reports, an important conclusion is that achieving automation requires a culture that fosters innovation and encourages proactive adoption of technology. Leaders therefore need to embrace change and encourage employees to see automation as an opportunity to improve their skills and focus on higher value-added tasks.

Automation and technology provide powerful tools in the effort to exceed customer requirements. However, it is the human touch that has created a customer-centric ecosystem. The human workforce thus provides unique insights and experiences, enabling organizations to better understand and serve their diverse customer base. Thus, despite advances in automation, the reports emphasise the essential role of people.

In this sense, as technology expands the capabilities of workers, it frees up more time for value-added cognitive tasks such as creativity, ideation and innovation. Moreover, by providing continuous learning opportunities, companies can build a workforce that is seamlessly adaptable to an ever-evolving landscape. Companies can also use technology to analyse employee data and feedback to identify opportunities to improve employee satisfaction, innovation and performance.

“(…) It’s having the right culture and the right people in place to implement this technology and to bring it all together to exceed your customer demands and expectations – whether it’s fast delivery, personalization, low cost, delivery transparency or ESG goals.” (Environmental, social and governance goals)

John Paxton, Director general MHI

Technology can help today’s businesses redesign work and empower workers, making work better for people and people better for work. According to Deloitte’s 2023 survey, nearly all companies (93%) recognize the importance of using technology to improve workplace outcomes and employee performance, but only 22 companies said their organization is ready to do so. So we’re coming to your aid with our automation solutions to help make this a reality.

EUROFIT automation solutions for perfect synergy

Choosing the best automation solutions depends very much on your company’s specific needs and requirements, your industry, warehouse size, volume of operations and overall goals. However, some of our solutions stand out for their potential to create a seamless integration between technology and human workforce:

- Goods-to-Person (G2P) systems reduce time wasted on moving and searching by having automated robots bring goods directly to workers. This reduces the physical fatigue of employees, allowing them to focus on other more important tasks, while technology takes care of repetitive aspects that require time and intense physical effort. EUROFIT offers the following solutions: AS/RS Mini Load system, Stacker Crane, ACR (Autonomous Case-handling robot), Vertimag system (vertical storage), Shuttle System or the Intelligent High-Density 3D Shuttle System, as well as AGV (Automatic Guided Vehicle) system.

- AutoStore is a compact and modular robotic solution that maximizes your warehouse capacity and picking or storage processes. Its flexible design allows it to easily adapt to changing warehouse needs and works in tandem with humans to optimize space and streamline processes.

- Conveyor and sorting systems are essential components of warehouse automation and play a vital role in streamlining material handling and order fulfillment. These systems are versatile and widely used in a variety of industries to efficiently move goods through warehouses, sort items for packaging or distribution, and streamline overall logistics operations, making your employees’ jobs easier.

- The A-Frame system is very flexible and suitable for fast order processing of small, fast-moving stock items. By automating the handling of these items, workers can focus on more complex tasks, helping to improve productivity and optimise material flow.

- Augmented systems (Pick-by-Light and Pick-to-Light) guide warehouse workers to the right locations, improving the accuracy and efficiency of the picking process. Technology complements human capabilities by streamlining the picking process and minimizing errors.

- The ParcelCube™ weighing and volumetric system is ideal for inbound and outbound logistics, helping workers accurately weigh and measure items. By automating the measurement process, workers can manage packages more efficiently and transmit data directly to your warehouse WMS system.

- End-of-Line systems ensure that products are properly packaged and ready for delivery to your customers. By automating the packaging process, workers can focus on more important tasks, helping to fill orders faster and increase efficiency. Solutions include pallet inspection systems, palletising and depalletising systems, automated pallet wrapping systems, stacker/destacker equipment and scanning and labelling equipment.

Automation has become a driving force in the warehouse industry, with technology and robotics taking centre stage. However, the need for human labour is still indispensable and the close link between technology and people is key to exceeding customer expectations.

EUROFIT stands by your side on your journey to automation with a complete portfolio of solutions tailored to any need. Harnessing the collaboration between technology and human potential, automation can transform your workplace for the better and deliver exceptional results, and with us as your trusted partner, you will achieve outstanding performance.

Source: “Annual Industry Report / The 2023 MHI Annual Industry Report / The 2022 MHI Annual Industry Report”, MHI, Deloitte; available here.